ABOUT

HOW IT WORKS

The

multi-award

winning

moladi

construction

system

was

founded

in

South

Africa

in

1986

as

a

method

of

building

cast

in

place

reinforced

monolithic

structures.

The

moladi

technology

was

developed

as

a

means

to

alleviate

many

of

the

cumbersome

and

costly

aspects

associated

with

conventional

construction methods without compromising on the quality or integrity of the structure.

The

moladi

system

constitutes

the

use

of

a

removable,

reusable,

recyclable

and

lightweight

plastic

formwork

mould,

which

is

filled

with

a

South

African

Bureau

of

Standards

approved

and

Agrément

Certified

aerated

mortar

to

form

the

wall

structure

of

a

house

in

as

little

as

one

day.

Each

set

of

moladi

formwork

panels

can

be

re-used

50

times

making

the

technology

cost

effective

due

to

its

repetitive

application

scheme,

reducing

the

cost

of

construction

and

transportation

significantly. The

moladi

system produces durable and permanent structures, which have been subject to numerous tests and independent reports.

The

process

involves

a

number

of

smaller

components

which

are

assembled

into

larger,

lightweight

panels

that

are

configured

into

a

mould

which

forms

a

house

of

any

desired

size

and

design.

The

engineer

specified

steel

reinforcing

bars,

window

and

door

block-outs,

conduits,

service

pipes

and

other

fittings

are

positioned

within

the

150mm

or

100mm

wall

cavity,

which

is

then

filled

with

a

specially

formulated

and

project

specific

lightweight

mortar

consisting

of

the

local

river

sand,

cement,

water,

and

a

harmless

cement

admixture

to

form

all

the

walls

of

the

house

simultaneously.

The

moladi

plastic

formwork

panels

are

then

removed

the

following

morning

and

immediately

re-erected

onto

an

adjoining

site.

The

result

is

a

wall

with

a

smooth

off-shutter

finish

that

does

not

require

any

plastering,

beam

filling or chasing and generates no waste. The walls are then painted, the roof erected and windows and doors are installed to complete the house.

The

moladi

construction

method

provides

structures

which

are

permanent,

durable,

waterproof,

and

possess

excellent

thermal

and

sound

insulation

properties.

The

moladi

walls

possess

an

average

compressive

strength

of

15MPa

or

15N/mm²,

which

is

far

stronger

than

the

average

standard

for

cement

blocks

which

vary from 3.6 N/mm² and 7N/mm² or common clay building bricks, which have a compressive strength of 5.2N/mm².

moladi

’s

principle

methodology

is

aimed

at

eliminating

all

of

the

typical

problems

one

encounters

with

construction

projects,

such

as

time

constraints,

shortage

of

skilled

labour

and

materials

as

well

as

waste.

It

is

the

simplicity,

performance,

functionality

and

practicality

of

the

moladi

technology

which

contributes

to

the

affordability of

moladi

homes which are roughly 30% less than similar structures built using the traditional brick and mortar method.

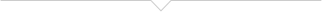

The structural requirements for the Raft

Foundation are determined by a professional

local Engineer. The Raft foundation is ultimately

more cost effective to build, is less time and

labour intensive, is far more accurate and is

suitable for all ground conditions

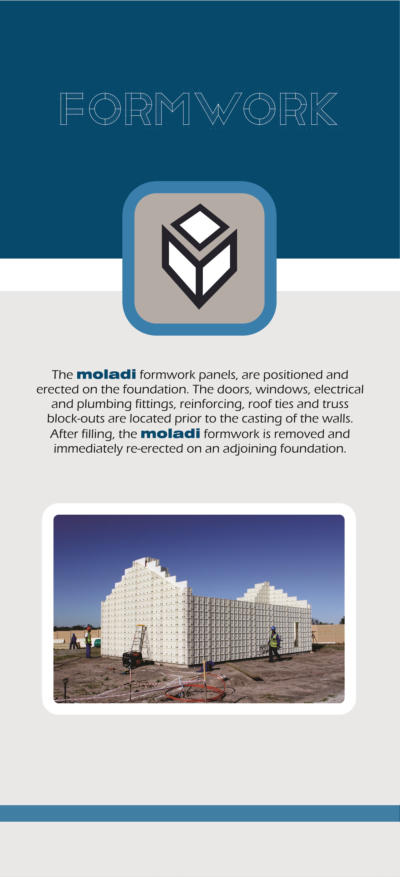

The moladi formwork panels are positioned

and erected on the foundation. The doors,

windows, electrical and plumbing fittings,

reinforcing, roof ties and truss block-outs are

located prior to the casting of the walls. After

filling, the panels are removed and immediately

re-erected on an adjoining foundation.

The mix ratios of cement, river sand, water and

moladiADMIX is determined by laboratory

testing of the local aggregate. The specialised

moladi mortar mix is then mixed on site and

is either manually dispatched or pumped into the

formwork cavity. The moladi formwork can be

removed the next morning.

ABOUT

HOW IT WORKS

The

process

involves

a

number

of

smaller

components

which

are

assembled

into

larger,

lightweight

panels

that

are

configured

into

a

mould

which

forms

a

house

of

any

desired

size

and

design.

The

engineer

specified

steel

reinforcing

bars,

window

and

door

block-outs,

conduits,

service

pipes

and

other

fittings

are

positioned

within

the

150mm

or

100mm

wall

cavity,

which

is

then

filled

with

a

specially

formulated

and

project

specific

lightweight

mortar

consisting

of

the

local

river

sand,

cement,

water,

and

a

harmless

cement

admixture

to

form

all

the

walls

of

the

house

simultaneously.

The

moladi

plastic

formwork

panels

are

then

removed

the

following

morning

and

immediately

re-erected

onto

an

adjoining

site.

The

result

is

a

wall

with

a

smooth

off-shutter

finish

that

does

not

require

any

plastering,

beam

filling

or

chasing

and

generates

no

waste.

The

walls

are

then

painted,

the

roof

erected

and

windows

and

doors

are installed to complete the house.

The

moladi

construction

method

provides

structures

which

are

permanent,

durable,

waterproof,

and

possess

excellent

thermal

and

sound

insulation

properties.

The

moladi

walls

possess

an

average

compressive

strength

of

15MPa

or

15N/mm²,

which

is

far

stronger

than

the

average

standard

for

cement

blocks

which

vary

from

3.6

N/mm²

and

7N/mm²

or

common

clay

building

bricks,

which

have

a

compressive strength of 5.2N/mm².

moladi

’s

principle

methodology

is

aimed

at

eliminating

all

of

the

typical

problems

one

encounters

with

construction

projects,

such

as

time

constraints,

shortage

of

skilled

labour

and

materials

as

well

as

waste.

It

is

the

simplicity,

performance,

functionality

and

practicality

of

the

moladi

technology

which

contributes

to

the

affordability

of

moladi

homes

which

are

roughly

30%

less

than

similar

structures

built using the traditional brick and mortar method.

Each set of moladi

formwork panels can be re-used

50 times making the technology

cost effective due to its repetitive

application scheme, reducing the

cost of construction and

transportation significantly.

The

process

involves

a

number

of

smaller

components

which

are

assembled

into

larger,

lightweight

panels

that

are

configured

into

a

mould

which

forms

a

house

of

any

desired

size

and

design.

The

engineer

specified

steel

reinforcing

bars,

window

and

door

block-outs,

conduits,

service

pipes

and

other

fittings

are

positioned

within

the

150mm

or

100mm

wall

cavity,

which

is

then

filled

with

a

specially

formulated

and

project

specific

lightweight

mortar

consisting

of

the

local

river

sand,

cement,

water,

and

a

harmless

cement

admixture

to

form

all

the

walls

of

the

house

simultaneously.

The

moladi

plastic

formwork

panels

are

then

removed

the

following

morning

and

immediately

re-erected

onto

an

adjoining

site.

The

result

is

a

wall

with

a

smooth

off-shutter

finish

that

does

not

require

any

plastering,

beam

filling

or

chasing

and

generates

no

waste.

The

walls

are

then

painted,

the

roof

erected

and

windows

and

doors

are installed to complete the house.

The

moladi

construction

method

provides

structures

which

are

permanent,

durable,

waterproof,

and

possess

excellent

thermal

and

sound

insulation

properties.

The

moladi

walls

possess

an

average

compressive

strength

of

15MPa

or

15N/mm²,

which

is

far

stronger

than

the

average

standard

for

cement

blocks

which

vary

from

3.6

N/mm²

and

7N/mm²

or

common

clay

building

bricks,

which

have

a

compressive strength of 5.2N/mm².

moladi

’s

principle

methodology

is

aimed

at

eliminating

all

of

the

typical

problems

one

encounters

with

construction

projects,

such

as

time

constraints,

shortage

of

skilled

labour

and

materials

as

well

as

waste.

It

is

the

simplicity,

performance,

functionality

and

practicality

of

the

moladi

technology

which

contributes

to

the

affordability

of

moladi

homes

which

are

roughly

30%

less

than

similar

structures

built using the traditional brick and mortar method.

ADDRESS

PO Box 16553

Emerald Hill

Port Elizabeth

South Africa

6011

Copyright reserved © Terms of use apply

NAVIGATION

SOCIAL

ADDRESS

PO Box 16553

Emerald Hill

Port Elizabeth

South Africa

6011

Copyright reserved © Terms of use apply

NAVIGATION

SOCIAL